X

This site uses cookies. By continuing to use this site you agree to our use of cookies. To find out more, see our Privacy Policy and Cookie Policy.

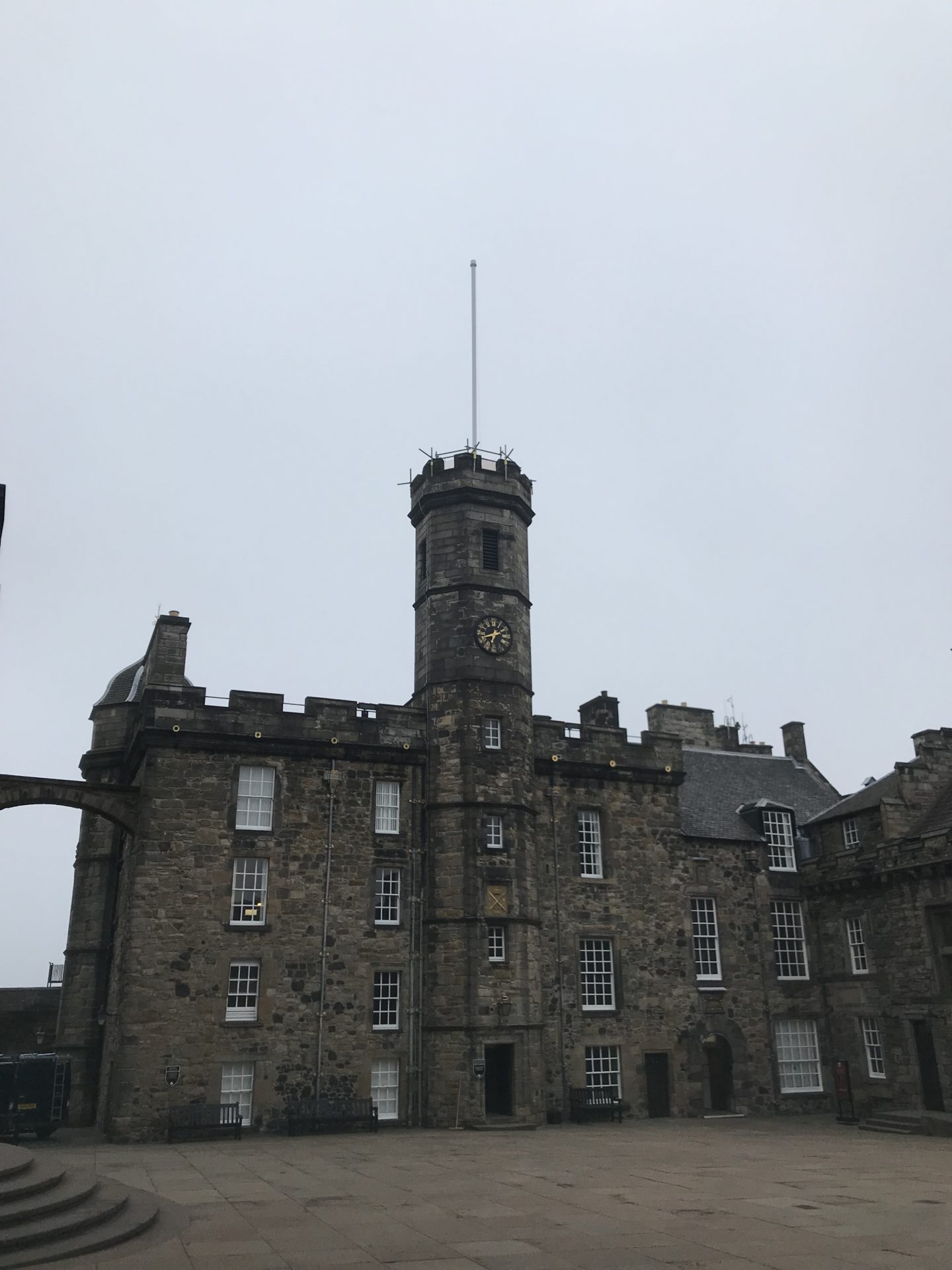

Harrisons were asked to design a 14m flagpole for the top of the clock tower at Edinburgh Castle incorporating an internal winch mechanism to raise and lower the flag and a custom winch mechanism to lower the flagpole from inside the clock tower.

Harrison Flagpoles have worked on a number of projects on listed buildings and are well acquainted with working sensitively to protect these iconic monuments. Whilst our flagpoles already adorn parts of Edinburgh Castle, Harrisons were extremely honoured to be commissioned to design and install this replacement flagpole for the tower.

Even as the UK’s leading specialist in this field the custom flagpole required for this project offered an exciting proposition for our design team.

This project presented a host of challenges. It utilised Harrison Flagpoles design skills, built up over many years of designing, manufacturing and installing flagpoles for complex projects, to the full.

Challenge 1: Extreme conditions

The iconic Edinburgh Castle dominates the skyline of the city of Edinburgh in Scotland. It’s position on Castle Rock with its summit of 130 metres (430 ft) above sea level makes it the most exposed and highest point in Edinburgh. Although it is recommended that flagpoles are taken down in high winds, the client wanted the extra reassurance that the pole could withstand windspeeds of up to 140mph when flagged.

Challenge 2: Minimal access to the roof for day-to-day use

The client required a solution that would negate the need to climb the flagpole for cleaning and servicing. Ordinarily a hinge base plate would be used so a flagpole can be lowered to 90 degrees, however due to the location on top of the tower this was not possible. Instead, a custom solution would need to be sought. The client also wanted to minimise the need to access the roof to lower and change flags. The flagpole and flag would need to be raised and lowered from within the tower as and when necessary.

Challenge 3: Installation restrictions

Access for installation was also an issue. Dropping the pole in to position on the top of the clock tower was not an option so it would need to be brought through the castle and up a tight spiral staircase within the tower. As space was restricted a solution was needed that ensured the flagpole could be installed without any damage to the Grade I listed building. The flagpole also needed to fit through the existing hole in the roof and operate around a unique cruciform structure within the tower.

This complex project was managed by Harrison’s team of experts from start to finish with an incredible level of support from the client, Bell Group.

The right material for the conditions

Selecting the right material for the flagpole to meet the wind speed requirement was essential. A galvanised Grade S355 mild steel was selected and the pole diameter and wall thickness were designed and calculated specifically to ensure the flagpole would withstand windspeeds of 145mph when flagged. The steel flagpole was hot dip galvanised and painted in house to a specialist finish to ensure durability in a harsh environment. This type of paint is typically used on commercial vehicles due to its excellent exterior durability and chemical resistance. It will typically have a service life of 10 years before maintenance is required.

Operating the flagpole

A halyard/roping system is used to raise and lower a flag on a flagpole. It can be housed internally or externally to the pole depending upon requirements. It is traditionally operated from the foot of the pole, however, in this case it would mean accessing the roof each time the flag needed to be lowered or changed. As safety was an issue we added an internal winch mechanism that could be accessed from within the tower. This removed the need to stand on the narrow clock tower roof to change the flag.

As the client required a safe means to service the flagpole and in the case of an extreme storm protect the pole Harrisons designed a flagpole that can be lowered via a heavy duty winch and pulley system secured within the tower. A specially designed guide sleeve housed within the tower guides the main flagpole allowing it to be raised and lowered within a limited space and to a very specific alignment. The design and operation offers a truly unique solution to an extremely challenging brief. The pole can be lowered to within 180cm of the roof level allowing all parts of the pole to be accessed safely for cleaning or maintenance.

Installation

Installation of the flagpole presented a number of significant challenges. The pole could not be lifted by crane and therefore had to be manually lifted piece by piece, up six storeys, around a tight spiral staircase to the top of the tower. Manufactured in four sections weighing approximately 170 kilos each the flagpole was joined and assembled within the tower, section by section. As the castle is a Grade I listed building the team were extremely sensitive to the structure of the building as well as health and safety procedures.

Harrisons are very proud to have been invited to undertake this complex and challenging project and the flagpole now sits pride of place overlooking the beautiful city.

If you would like to find out more about the products discussed in this case study, please do not hesitate to speak to one of our specialist advisers.

Call 01325 390 195 or email sales@weareharrisons.com

If you’d prefer us to contact you leave your details in the form opposite and we’ll get back to you as soon as we can.